Description

MAIN TECHNICAL FEATURE

Characters

Fully Rustproof and corrosion resistant

High strength Light weight

Easy transporting and installation

Nice appearance

Structure & Materials

Liner material: Rotation molding or Blowing One-piece seamless PE inner liner

Outer Winding: Hight Performance resin with Fiber glass threedimensional winding

Opening: 2.5″ and 4″ reinforced plastic thread,6″ alloy flange

Bass Materials: FRP or reinforced PP

Application Conditions

Working Pressure:150psi (10.5bar)

Working Temperature:1-49*C (34-121*F)

Max.Vacuum:127mm Hg

Lowest Environment Temperature: -27*C (-17*F)

Design Parameter

Burst Pressure: 42bar (4 times)

Fatigue Cycle: 100, 000

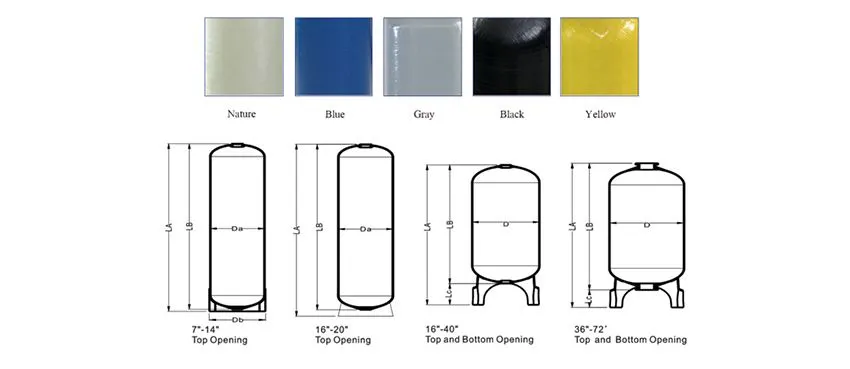

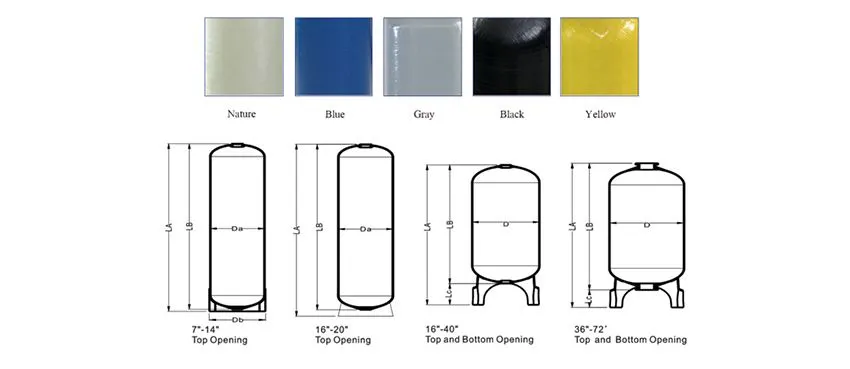

Color

In UMK fiber reinforced polymer tanks, there are five colors for your choose : Nature,

Blue, Black, Gray, Yellow. ( Other colors are customied )

Specification

AMANDA TANK SPECIFICATION

| Model |

Vessel Size |

Vol |

Opening |

Dimension/mm |

Base |

| Inch |

mm |

L |

Top |

Bot. |

LA |

LB |

LC |

D |

| 2165/4T |

21×65 |

550x 1640 |

322 |

4″-8UN |

/ |

1640 |

1590 |

/ |

550 |

FRP Round |

| 2169/4T |

21×69 |

550×1750 |

322 |

4″-8UN |

/ |

1760 |

1590 |

/ |

550 |

FRP Tripod |

| 2169/4T4B |

21×69 |

550×1750 |

322 |

4″-8UN |

4″-8UN |

1760 |

1575 |

185 |

550 |

FRP Tripod |

| 2176/4T |

21×76 |

550×1910 |

326 |

4″-8UN |

/ |

1910 |

1600 |

320 |

550 |

FRP Round |

| 2176/4T4B |

21×76 |

550×1910 |

326 |

4″-8UN |

4″-8UN |

1910 |

1590 |

320 |

550 |

FRP Tripod |

| 2468/4T |

24×68 |

615×1735 |

427 |

4″-8UN |

/ |

1735 |

1690 |

/ |

615 |

FRP Tripod |

| 2472/4T |

24×72 |

615x 1850 |

427 |

4″-8UN |

/ |

1850 |

1690 |

/ |

615 |

FRP Round |

| 2472/4T4B |

24×72 |

615×1850 |

427 |

4″-8UN |

4″-8UN |

1850 |

1680 |

170 |

615 |

FRP Tripod |

| 2485/4T |

24×85 |

615×2150 |

471 |

4″-8UN |

/ |

2150 |

1830 |

/ |

615 |

FRP Tripod |

| 2485/4T4B |

24×85 |

918×2150 |

471 |

4″-8UN |

4″-8UN |

2150 |

1830 |

320 |

615 |

FRP Tripod |

| 3068/4T |

30×68 |

780×1730 |

690 |

4″-8UN |

/ |

1730 |

1690 |

/ |

780 |

FRP Tripod |

| 3072/4T |

30×72 |

780×1850 |

690 |

4″-8UN |

/ |

1850 |

1690 |

/ |

780 |

FRP Tripod |

| 3072/4T4B |

30×72 |

780×1850 |

690 |

4″-8UN |

4″-8UN |

1850 |

1680 |

175 |

780 |

FRP Tripod |

| 3085/4T |

30×85 |

780×2150 |

758 |

4″-8UN |

/ |

2150 |

1830 |

/ |

780 |

FRP Tripod |

| 3085/4T4B |

30×85 |

780x 2150 |

758 |

4″-8UN |

4″-8UN |

2150 |

1830 |

320 |

780 |

FRP Tripod |

| 3087/6T6B |

30×87 |

780x 2200 |

728 |

6″-flane |

6″-flange |

2200 |

1935 |

265 |

780 |

FRP Tripod |

| 3672/4T4B |

36×72 |

918x 1850 |

850 |

4″-8UN |

4″-8UN |

1850 |

1610 |

240 |

918 |

FRP Tripod |

| 3685/4T4B |

36×85 |

918x 2150 |

1023 |

4″-8UN |

4″-8UN |

2150 |

1830 |

320 |

918 |

FRP Tripod |

| 3689/6T6B |

36×89 |

918x 2260 |

1023 |

6″-flane |

6″-flange |

2260 |

1940 |

320 |

918 |

FRP Tripod |

| 3694/6T6B |

36×94 |

918x 2400 |

1205 |

6″-flane |

6″-flange |

2400 |

2140 |

260 |

918 |

FRP Tripod |

| 4072/4T4B |

40×72 |

1020x 1850 |

1046 |

6″-flane |

6″-flange |

1850 |

1605 |

245 |

1020 |

FRP Tripod |

| 4094/6T6B |

40×94 |

1020x 2400 |

1332 |

6″-flane |

6″-flange |

2400 |

2155 |

225 |

1020 |

FRP Tripod |

| 4272/6T6B |

42×72 |

1088x 1850 |

1100 |

6″-flane |

6″-flange |

1850 |

1615 |

235 |

1088 |

FRP Tripod |

| 4289/6T6B |

42×89 |

1088x 2270 |

1389 |

6″-flane |

6″-flange |

2270 |

1950 |

320 |

1088 |

FRP Tripod |

| 4872/6T6B |

48×72 |

1218x 1850 |

1308 |

6″-flane |

6″-flange |

1850 |

1565 |

285 |

1218 |

FRP Tripod |

| 4889/6T6B |

48×89 |

1218x 2270 |

1743 |

6″-flane |

6″-flange |

2270 |

1950 |

320 |

1218 |

FRP Tripod |

| 4894/6T6B |

48×94 |

1218x 2400 |

1909 |

6″-flane |

6″-flange |

2400 |

2110 |

290 |

1218 |

FRP Tripod |

| 48110/6T6B |

48×110 |

1218x 2800 |

2360 |

6″-flane |

6″-flange |

2800 |

2510 |

290 |

1218 |

FRP Tripod |

| 6094/6T6B |

60×94 |

1530x 2400 |

2688 |

6″-flane |

6″-flange |

2400 |

2110 |

290 |

1530 |

FRP Tripod |

| 60110/6T6B |

60×110 |

1530x 2800 |

3392 |

6″-flane |

6″-flange |

2800 |

2510 |

290 |

1530 |

FRP Tripod |

| 6383/6T6B |

63×83 |

1620x 2100 |

2580 |

6″-flane |

6″-flange |

2100 |

1780 |

320 |

1620 |

FRP Tripod |

| 6394/6T6B |

63×94 |

1620x 2400 |

3150 |

6″-flane |

6″-flange |

2400 |

2080 |

320 |

1620 |

FRP Tripod |

| 7294/6T6B |

72×94 |

1836x 2400 |

3561 |

6″-flane |

6″-flange |

2400 |

2045 |

355 |

1836 |

FRP Tripod |

*The actual dimension may have ±1.2% error due to PE materials contraction coefficient

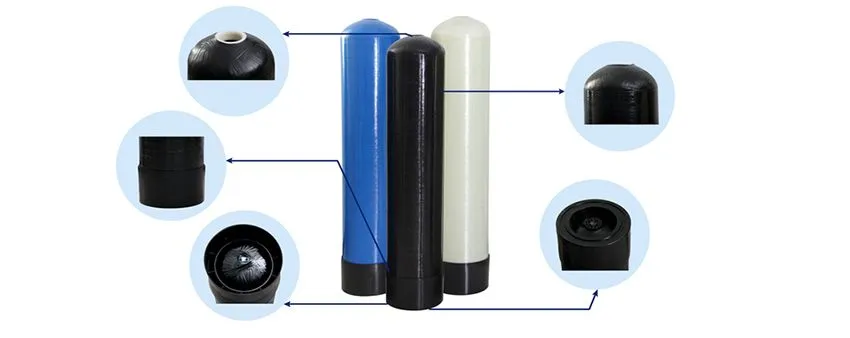

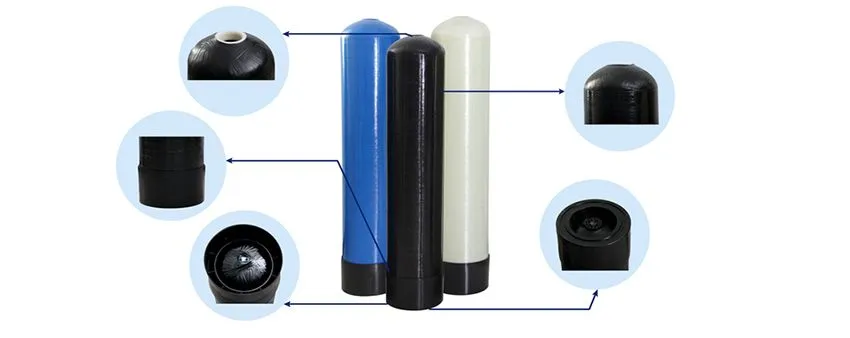

PRODUCT DISPLAY

Product advantage:

FRP tank is made up of resin and glass fiber by microcomputer control winding machine and become a kind of non-metallic

composite tanks. it has corrosion resistance. high strength. long service life. can be flexible design workmanship, etc

PRODUCING PROCESS

fiber reinforced polymer tanks processes used for manufacturing :

1. 6” to 36″ PE liners are made from CNC controlled blow molding machine ,

2. PE liner of industrial tanks are made from CNC controlled rotational molding machine ,

3. Inlet inserts and bases are from CNC controlled injection molding machine,

4. FRP outer shells are made from CNC controlled multi-axis filament winding machine.